Innovations in Toy Manufacturing: What’s New in 2024

The toy manufacturing industry in 2024 is a vibrant landscape of innovation, creativity, and technology. As manufacturers blend tradition with technology, the result is a new era of toys that are more interactive, educational, and sustainable than ever before. This year promises exciting developments that not only captivate the imaginations of children but also address pressing global issues such as sustainability and education through play.

- Introduction

- Historical Evolution of Toy Manufacturing

- Current Trends in Toy Manufacturing

- Technological Advancements in Toy Manufacturing

- The Role of Artificial Intelligence in Toy Manufacturing

- Sustainable Practices in Toy Manufacturing

- The Business of Toy Manufacturing in 2024

- Innovations in Toy Manufacturing

- Conclusion

Introduction

In the heart of the 21st century, the toy manufacturing industry is undergoing a transformative phase, characterized by rapid advancements in technology and a growing awareness of environmental and societal responsibilities. The year 2024 marks a pivotal point in this journey, showcasing innovative approaches to toy design and production that are set to redefine the play experiences of future generations.

This comprehensive exploration into “Innovations in Toy Manufacturing: What’s New in 2024″ delves into the core of current trends, technological breakthroughs, and the evolving landscape of toy manufacturing. From leveraging renewable resources to embracing digital integration, the industry is not just evolving; it’s leading the charge towards a more sustainable, inclusive, and technologically enriched future.

Historical Evolution of Toy Manufacturing

Reflecting on the past, the journey from handcrafted wooden toys to today’s high-tech playthings illustrates a fascinating evolution. Early toy manufacturing was a meticulous, hands-on process, with artisans crafting each piece with care and precision. Fast forward to 2024, and the industry is a blend of art and science, where automation and digital design have revolutionized production methods. This section would explore this transformation, emphasizing how technological advancements have continuously shaped toy manufacturing.

Current Trends in Toy Manufacturing

Eco-friendly Materials and Sustainable Practices

Sustainability is no longer a buzzword but a guiding principle in toy manufacturing. In 2024, the industry is witnessing a surge in the use of biodegradable, recycled, and non-toxic materials. Companies are innovating with plant-based plastics, organic textiles, and even upcycled components, ensuring that toys are not just safe for children but also for the planet. This shift towards eco-conscious manufacturing is driven by a growing consumer demand for products that align with their values of environmental stewardship.

Digital Integration and Smart Toys

The digital age has ushered in a new era of smart toys, blending physical play with digital experiences. In 2024, toys are more connected than ever, with features like app integration, AR-enhanced learning, and interactive storytelling. These innovations offer children immersive and educational play experiences, bridging the gap between physical toys and the digital world. Manufacturers are exploring ways to make these technologies accessible and safe, ensuring that digital integration enhances play without compromising privacy or security.

Personalization and Customization

Personalization is at the forefront of toy manufacturing in 2024, with companies leveraging technology to offer bespoke toys tailored to individual preferences and needs. From customizable dolls that celebrate diversity to build-your-own robot kits, the industry is embracing the idea that play should be as unique as the child. This trend not only enhances the play experience but also fosters a deeper emotional connection between children and their toys.

Technological Advancements in Toy Manufacturing

The toy industry is undergoing a significant transformation, fueled by rapid technological advancements that are reshaping how toys are designed, produced, and interacted with. As we move into 2024, several key technologies stand out for their impact on toy manufacturing, promising to bring innovative products to market and redefine the play experience for children and adults alike. Let’s delve into the forefront of these advancements.

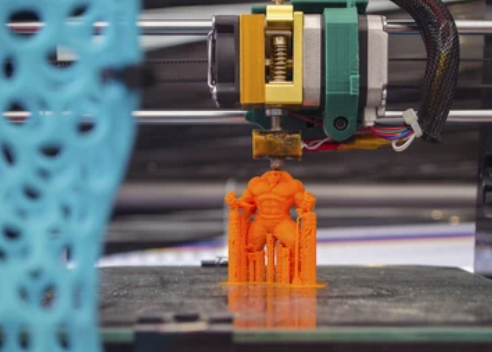

3D Printing and Its Impact

3D printing technology has revolutionized the toy manufacturing industry by enabling more intricate designs, rapid prototyping, and the ability to produce toys on demand. This technology allows manufacturers to quickly move from concept to prototype to final product, reducing development time and costs significantly. It also opens the door for custom-made toys, where consumers can personalize their purchases, choosing colors, shapes, and even adding names or messages to create truly unique items. The flexibility of 3D printing means that small batches of toys can be produced economically, encouraging innovation and allowing manufacturers to test the market with niche products before committing to large-scale production.

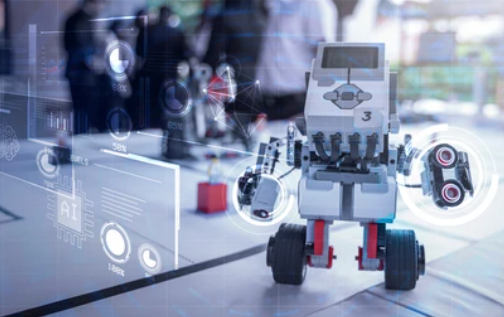

Robotics and Automation in Production

Robotics and automation have been game-changers in the toy manufacturing industry, leading to increased efficiency, reduced costs, and improved quality. Automated production lines can operate 24/7, ensuring a faster turnaround time from design to shelf. Robotics in toy manufacturing not only streamlines the assembly process but also enhances precision in the production of complex parts, leading to higher-quality products. Furthermore, automation reduces the reliance on manual labor, which can be especially beneficial in tasks that require high consistency or involve hazardous materials, ensuring a safer working environment.

Virtual Reality (VR) and Augmented Reality (AR) in Toy Design

Virtual reality (VR) and augmented reality (AR) are taking toy design into new realms, offering immersive experiences that blend physical play with digital innovation. These technologies allow children to interact with their toys in ways that were previously unimaginable, from educational AR puzzles that bring history to life to VR playsets that transport users to fantastical worlds. By integrating VR and AR into toy design, manufacturers can create engaging and interactive products that encourage creativity, learning, and active play. Additionally, these technologies offer new opportunities for inclusive play, making games and toys more accessible to children with different needs and abilities.

The Role of Artificial Intelligence in Toy Manufacturing

In the ever-evolving landscape of toy manufacturing, artificial intelligence (AI) stands out as a beacon of innovation, reshaping the way toys are conceived, designed, and produced. As we step into 2024, the integration of AI into the toy manufacturing process is not just a trend but a significant shift towards creating more personalized, engaging, and safer toys for children around the globe. Let’s explore how AI is making its mark in this vibrant industry.

AI-driven Design Processes in Toy Manufacturing

Artificial intelligence is revolutionizing the design phase of toy manufacturing by enabling more sophisticated and efficient processes. AI-driven tools can analyze vast amounts of data, including consumer trends, feedback, and purchasing behaviors, to predict what kinds of toys will be most successful. This predictive analysis helps designers and manufacturers to focus their efforts on products that are more likely to resonate with their target audience. Furthermore, AI can assist in the actual design of toys, offering suggestions for improvements and innovations by analyzing existing designs and incorporating elements that enhance playability, educational value, and engagement.

Customization through Machine Learning in Toy Manufacturing

Machine learning, a subset of AI, is at the forefront of personalizing the toy experience. By learning from individual user interactions, machine learning algorithms can adapt toys to suit the preferences and developmental stages of each child. For instance, educational toys equipped with machine learning technology can adjust the difficulty level of puzzles or quizzes based on the child’s learning pace, providing a customized learning experience that grows with the child. This level of personalization not only enhances the play experience but also fosters a deeper connection between children and their toys, making playtime more rewarding and educational.

Safety and Quality Control

AI plays a crucial role in ensuring the safety and quality of toys. Through advanced image recognition and machine learning algorithms, AI systems can inspect toys at various stages of the manufacturing process, identifying defects or potential safety hazards that may be missed by the human eye. This includes checking for small parts that could pose choking hazards, ensuring the strength and durability of materials, and verifying that the final product meets all safety standards and regulations. By automating the quality control process, manufacturers can ensure that every toy that leaves the factory is safe, durable, and of the highest quality, giving parents peace of mind and building trust in the brand.

Sustainable Practices in Toy Manufacturing

As the global focus on environmental sustainability intensifies, the toy manufacturing industry is undergoing a transformative shift towards greener practices. In 2024, sustainable manufacturing is not just a niche trend but a core aspect of the industry’s evolution, reflecting a growing commitment to protect our planet while delighting children with innovative and eco-friendly toys. Let’s explore how sustainable practices are reshaping toy manufacturing, from the use of recycled materials to energy-efficient processes and compliance with global environmental standards.

Use of Recycled Materials

One of the most significant steps towards sustainability in toy manufacturing is the increasing use of recycled materials. Manufacturers are turning to post-consumer plastics, recycled wood, and other eco-friendly materials to create toys that are both safe for children and kind to the environment. This shift not only helps reduce the industry’s carbon footprint by minimizing the demand for new raw materials but also addresses the global challenge of plastic waste. Toys made from recycled materials are designed to be durable, ensuring they last longer and can be passed down or recycled, further promoting a circular economy within the toy industry.

Energy-efficient Manufacturing Processes

Energy efficiency is another critical focus for toy manufacturers aiming to reduce their environmental impact. Advances in technology have led to the development of more energy-efficient production methods, from the use of renewable energy sources, such as solar and wind power, to the implementation of smart manufacturing systems that optimize energy use. These systems can adjust energy consumption in real-time, based on the production needs, significantly reducing waste and lowering greenhouse gas emissions. By prioritizing energy efficiency, toy manufacturers not only contribute to a more sustainable planet but also benefit from reduced operational costs, making it a win-win situation.

Compliance with Global Environmental Standards

Compliance with global environmental standards is paramount for toy manufacturers committed to sustainability. Recognizing the importance of international cooperation in addressing environmental issues, many companies are aligning their practices with standards such as the ISO 14000 family, which focuses on effective environmental management systems. Compliance involves rigorous testing and certification processes, ensuring that toys are produced in a way that minimizes environmental harm. This commitment to environmental standards not only demonstrates a manufacturer’s dedication to sustainability but also builds trust with consumers who are increasingly seeking out eco-friendly products.

The Business of Toy Manufacturing in 2024

The toy industry is a vibrant and dynamic sector, constantly evolving to meet the changing demands of consumers and navigate the complexities of global markets. As we delve into 2024, several key factors are shaping the business landscape of toy manufacturing, from shifting market dynamics and consumer behavior to the challenges and opportunities presented by global supply chains. Understanding these elements is crucial for manufacturers looking to thrive in this competitive environment.

Market Dynamics and Consumer Behavior

In 2024, the toy manufacturing industry is witnessing significant shifts in market dynamics and consumer behavior. One of the most notable trends is the increasing demand for eco-friendly and sustainable toys, as consumers become more environmentally conscious. This shift is not just a preference but a strong buying criterion, with parents and educators seeking out products that align with their values of sustainability and responsibility. Additionally, the rise of digital technology has not only introduced a new category of smart and educational toys but also changed how consumers shop for toys, with online sales continuing to grow exponentially. Manufacturers must adapt to these changing dynamics, balancing the integration of technology with the demand for sustainable, high-quality products.

Challenges and Opportunities for Manufacturers

The current landscape presents both challenges and opportunities for toy manufacturers. One of the primary challenges is navigating the increased costs associated with sustainable materials and energy-efficient manufacturing processes. However, this also presents an opportunity to innovate and differentiate products in a crowded market. Additionally, the rapid pace of technological change requires manufacturers to continually invest in research and development to stay ahead of the curve, particularly in the realms of AI, robotics, and digital play experiences.

Another challenge is the highly competitive nature of the toy industry, where consumer preferences can shift rapidly, and the window for capitalizing on trends can be short. Manufacturers must be agile, able to quickly adapt their strategies and product lines to capture emerging market opportunities. This agility can also be a significant advantage, enabling manufacturers to lead in new product categories and create strong brand loyalty among consumers.

Impact of Global Supply Chains

Global supply chains play a crucial role in the toy manufacturing industry, affecting everything from cost and production timelines to environmental impact and product availability. The disruption of supply chains, as witnessed in previous years, highlighted the vulnerability of relying on extended networks for materials and production. In response, many manufacturers are reevaluating their supply chain strategies, looking towards diversification, nearshoring, or reshoring to mitigate risks. This reconfiguration offers the chance to improve resilience, reduce environmental impact through shorter transportation routes, and potentially capitalize on “made locally” consumer preferences.

Innovations in Toy Manufacturing

The year 2024 has brought with it a wave of fresh innovations in the realm of toy design, reshaping the way toys are created to meet the evolving demands of children and parents alike. These innovations are not just about introducing new gadgets and features; they’re about rethinking the entire design process to make it more inclusive, responsive, and responsible. Let’s delve into the cutting-edge trends that are defining toy design in 2024.

Collaborative Design Processes

The collaborative approach to toy design has emerged as a game-changer, breaking down the barriers between designers, manufacturers, and the end-users—children. This process leverages the power of crowdsourcing and co-creation workshops, inviting ideas and feedback from a broad spectrum of participants, including educators, parents, and kids themselves. By doing so, toy manufacturers are able to tap into a diverse pool of insights and creativity, leading to the development of toys that are not only innovative but also more aligned with what users truly want and need. This collaborative ethos ensures that toys are not only fun and engaging but also educational and developmentally appropriate.

Inclusion of Children’s Feedback

In 2024, the inclusion of children’s feedback in the design process has taken center stage, recognizing that children are not just consumers but also valuable contributors with unique perspectives. Toy companies are increasingly using platforms and tools that allow them to gather insights directly from children, be it through online surveys, focus groups, or interactive testing sessions. This direct feedback loop helps designers understand children’s preferences, play patterns, and usability issues, leading to the creation of toys that resonate more deeply with their intended audience. By valuing children’s voices, manufacturers can ensure their products foster joy, curiosity, and learning in the most effective ways.

Balancing Creativity with Safety

In the pursuit of innovation, the toy industry in 2024 continues to prioritize the delicate balance between creativity and safety. As toys become more complex and integrated with technology, ensuring they remain safe for children is paramount. Designers are employing advanced simulation tools and predictive analytics to anticipate potential safety issues early in the design process, allowing for adjustments before production begins. Moreover, there’s a growing emphasis on using non-toxic, sustainable materials that are not only safe for children but also for the environment. This commitment to safety does not stifle creativity; rather, it challenges designers to think outside the box and find novel solutions that meet stringent safety standards.

Conclusion

As we reflect on the remarkable journey of toy design innovations in 2024, it’s evident that the path towards creating toys that captivate, educate, and inspire has never been more dynamic. In an era marked by collaborative design processes, the inclusion of children’s feedback, and a steadfast commitment to balancing creativity with safety, the role of efficient sourcing and production becomes crucial. Herein lies the invaluable role of a China sourcing agent.

As we look towards the future, the collaboration between toy designers and China sourcing agents will undoubtedly continue to be a cornerstone of innovation in the toy industry. By leveraging the expertise of these agents, toy manufacturers can focus on what they do best—dreaming up the next generation of toys that ignite imagination, foster learning, and ensure safety. Together, they are setting the stage for a future where the toys we give our children are a reflection of our highest hopes for a world that is more creative, inclusive, and sustainable.

Recent Posts

- Budget-Friendly Imports: Strategies for Cost Control When Importing Goods From China

- Bridging Cultures: Navigating Cultural Aspects in China Imports

- Guide to working with a sourcing agent in China for startups

- How China Sourcing Agents Can Transform Your Business

- Exploring the Benefits of Collaborating with a China Sourcing Agent

Recent Comments